With special attention to the circular economy, we revolutionise production plants by reprogramming and digitising the latter for more efficient and functional performance. We operate in the plastic moulding sector, trying to minimise waste by remodelling machinery in a digital key, making them more effective, safe and reliable. We offer a reliable remodelling service and a range of products to optimise machinery management for companies operating in the plastics industry.

We created the acronym S.L.M. “Second Life Machinery” to give dynamism to our primary intent of “offering new life to industrial machinery “. Undeniably, the investment in the “new” machines leads to variable hourly production costs and the need to find financial sources to support the purchase. We want to obtain a worldwide revolution through a more aware usage of machinery and apparatus of the plastic material. Looking towards a Circular Economy, we believe it’s essential to promote the concept of waste reduction thanks to reprogramming the machine park in an intelligent key, assisting, at the same time, the companies in the plastic sector. As part of the refurbishment of our products, we provide technical assistance and spare part. Our interest is aimed at those who need the transformation of “CAPEX” assets in Italy and the rest of the world. We are projected towards all those companies in the plastics industry, including injection, extrusion, blow moulding or common pressure-related issues. Company

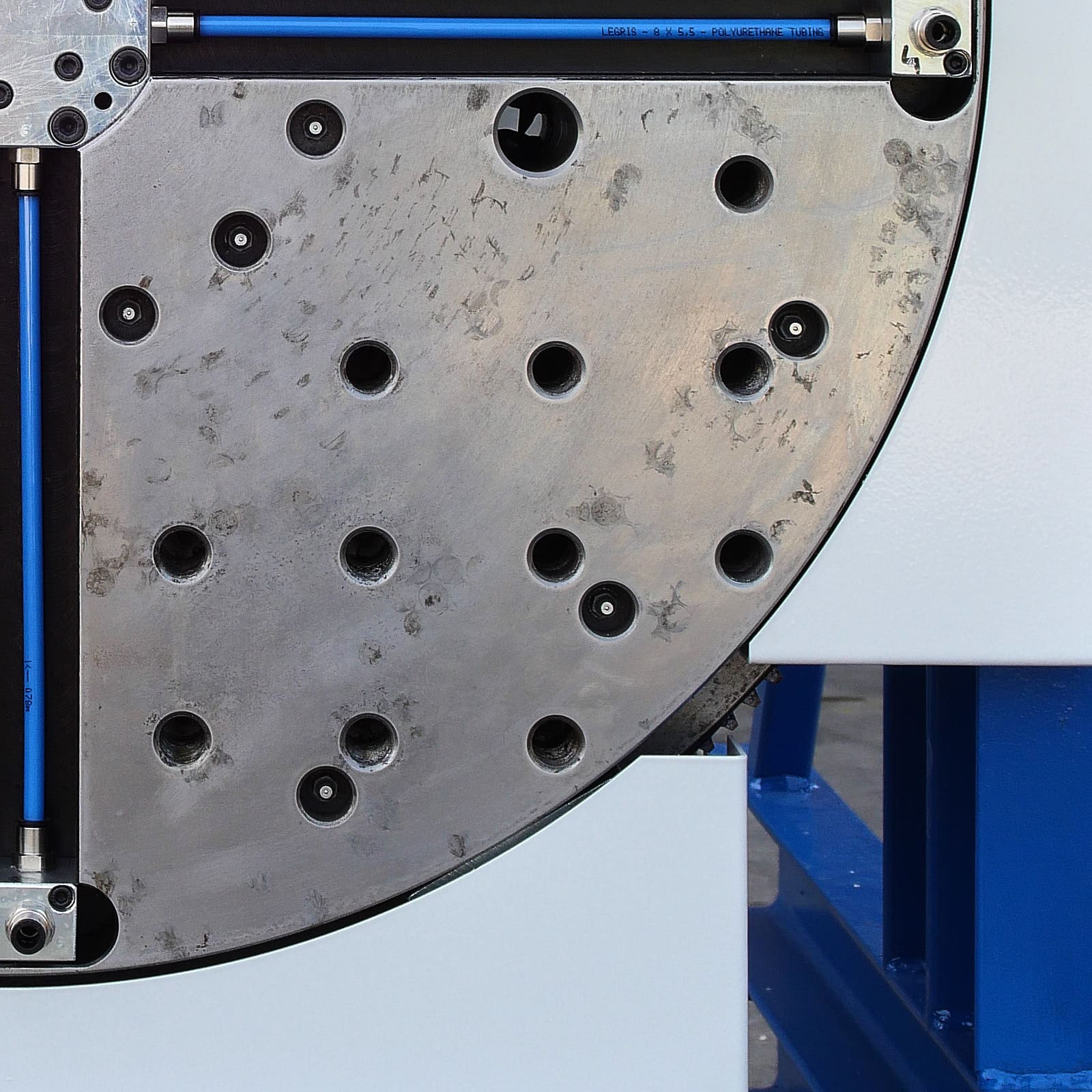

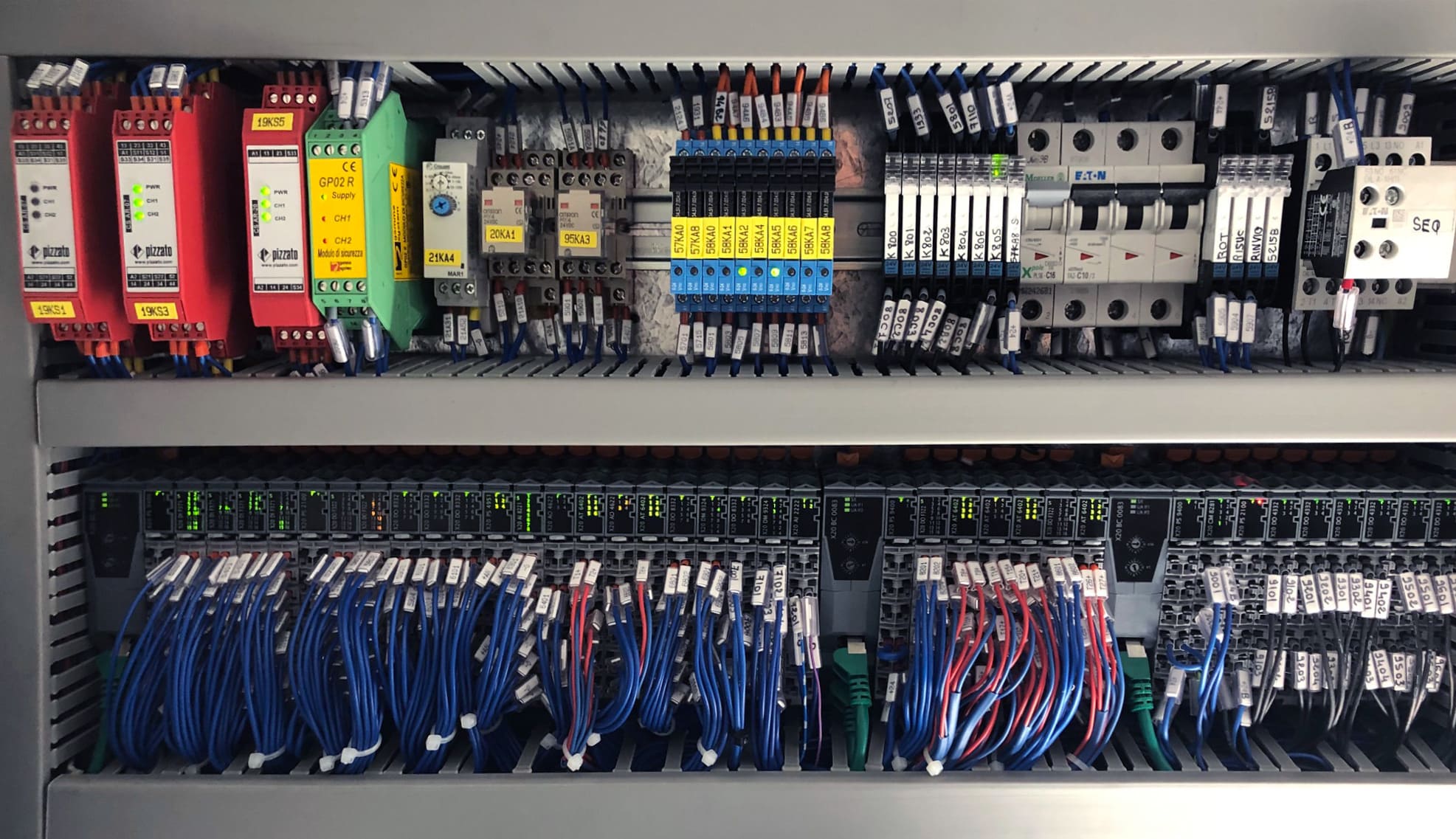

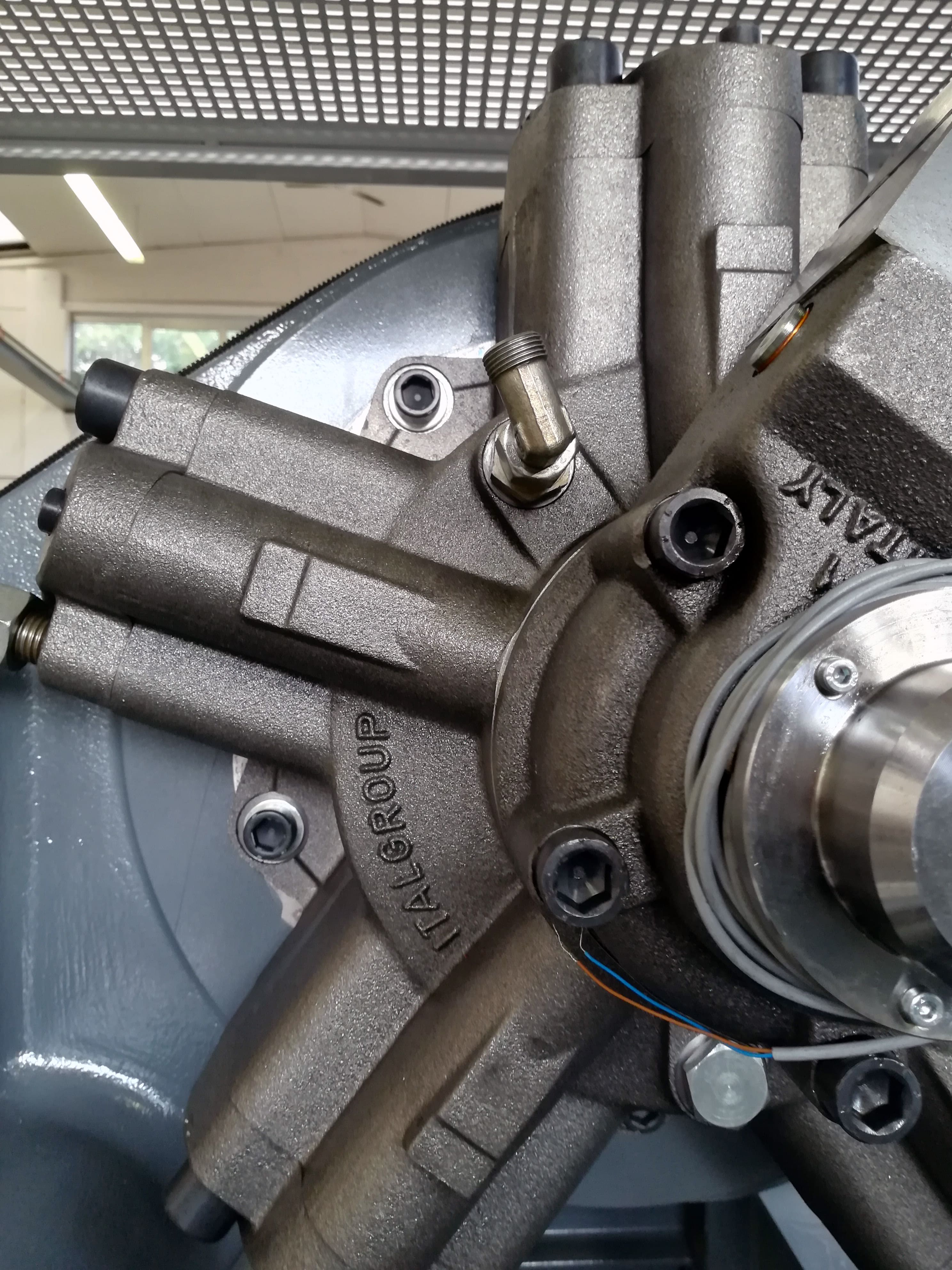

Reconditioning is our core business

Who we are

In the current and modest global plastic moulding market, we noticed an essential element was missing.

There was a need for someone to raise the competitiveness in the Circular Economy by also considering the economic return and adequate margins.

Our integrated projects use S.L.M. avant-garde products that transform and customise ordinary machinery into special ones, making them economically and environmentally sustainable.

Assets mainly were from non-European countries

that were disposed of or ended up with merchants who often sent them to non-European countries.

The latter have become real competitors in the Western market.

Our integrated projects use products designed by S.L.M. state-of-the-art machines that allow you to transform and customise standard machinery into special ones, making them sustainable from both an economic and environmental point of view.

Refurbished

What do we do?

We retire the plant destined for decommissioning

We check it in all structural parts

We redesign them adapting them to the needs of our customers

We use special equipment to improve its technology

Our customers

OUR KNOW-HOW INCLUDES THE ITALIAN PASSION AND FANTASY